CATERPILLAR -E395[CR6380,7Y-0856]front idler ass'y/cat excavator carriage part/E350/E365/E374D/E375/E390/E395 idler factory

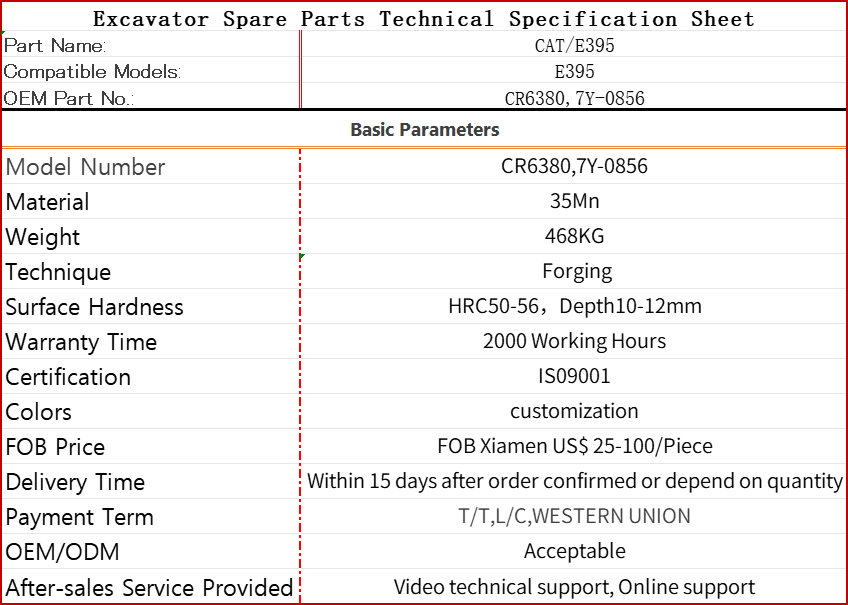

Product Specifications

CATERPILLAR -E395[CR6380,7Y-0856]front idler ass'y

Premium CAT395 Fabricated Front Idler Assembly

DPW Machinery supplies high-performance front idler assemblies for CAT395 excavators, engineered to withstand extreme mining and excavation conditions. Our fabricated steel construction ensures superior durability compared to standard cast idlers, reducing downtime and maintenance costs.

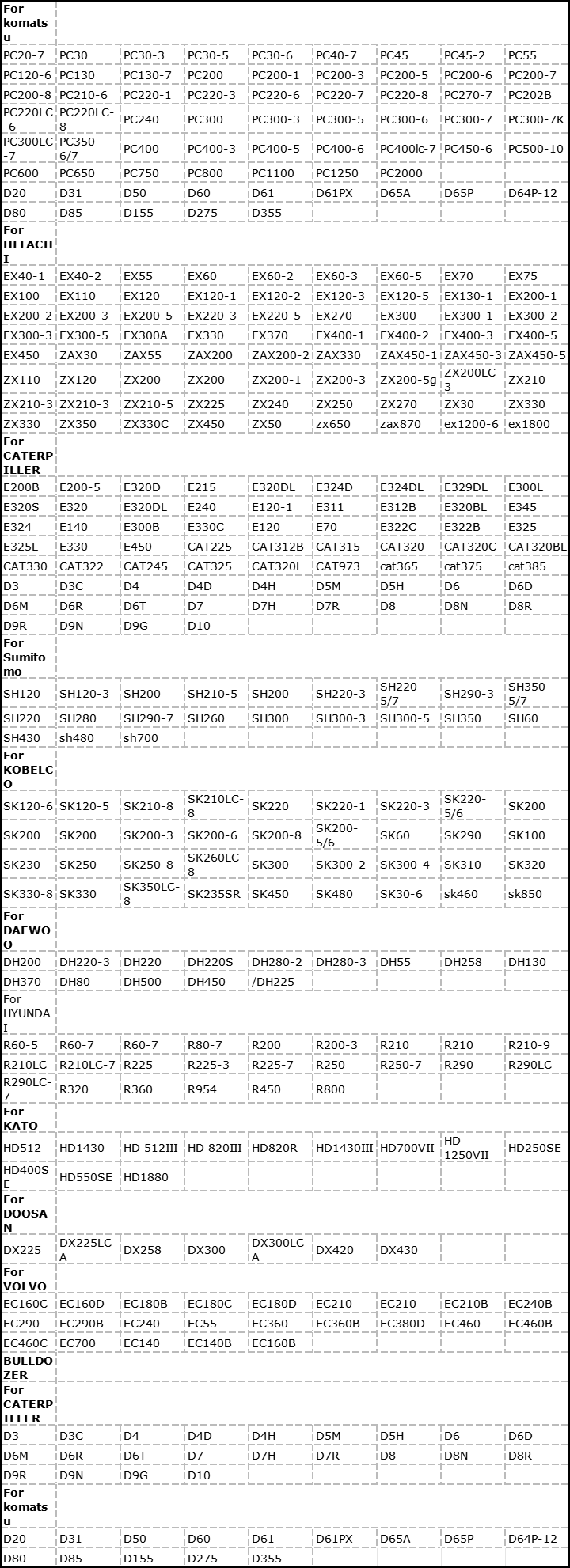

✔ OEM-Compatible Design – Precision-fit replacement for CAT395 undercarriages

✔ Reinforced for Heavy Loads – Ideal for mining, quarrying, and large-scale earthmoving

✔ Global Availability – Fast shipping for urgent replacements

Custom modifications available for specialized applications.

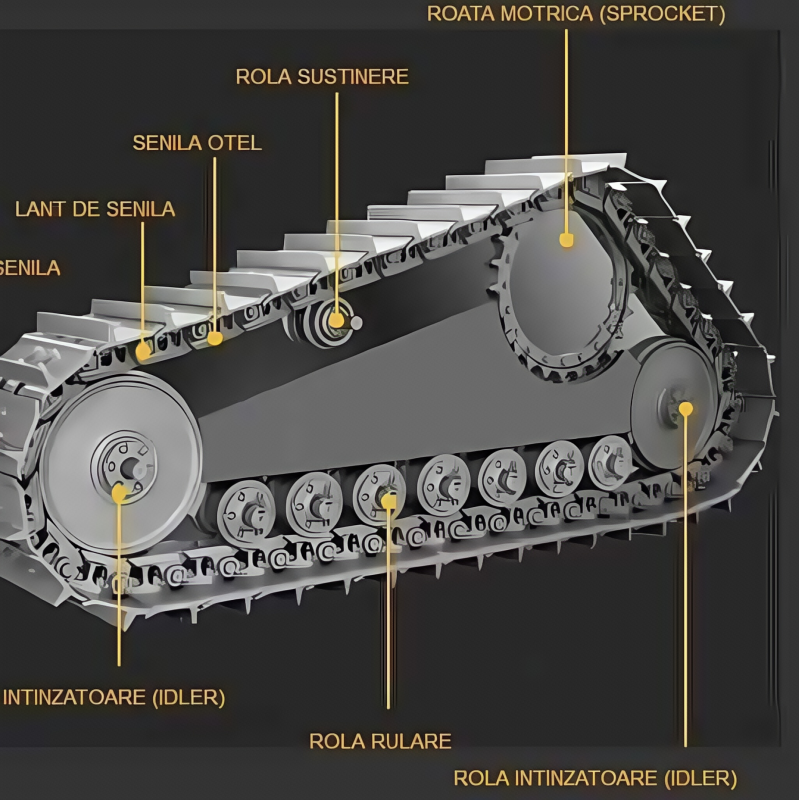

The Caterpillar E395 idler ass'y (idler assembly) is a crucial undercarriage component for the CAT E395 excavator, responsible for guiding and tensioning the track chain. Here’s detailed information to help you identify, replace, or maintain it:

1. Part Identification

Function:

Maintains track tension and alignment.

Absorbs shocks and supports the excavator’s weight during operation.

CAT Part Number:

Varies by machine configuration (standard/offset, with/without recoil spring).

Example: ****

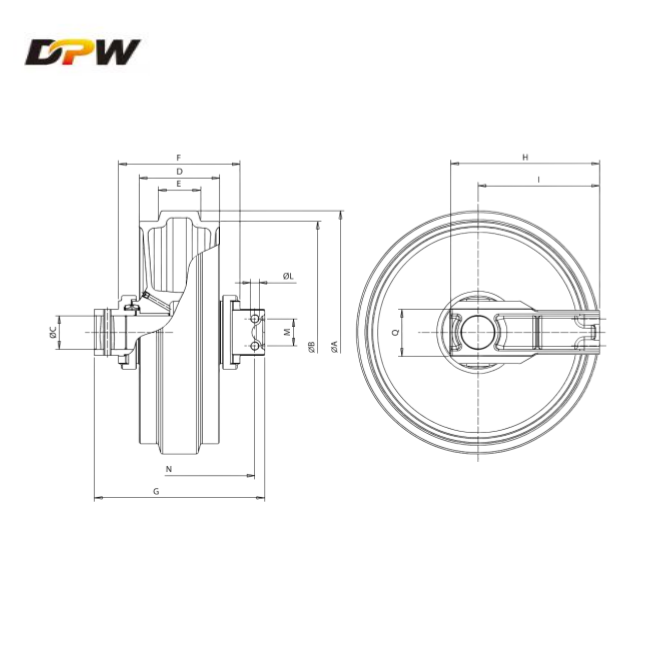

2. Replacement Specifications

Dimensions: Varies by model; measure old idler (shaft diameter, width, bolt pattern).

Compatibility: Ensure compatibility with E395 (other E-series models may differ).

Material: Typically forged steel with hardened surfaces for durability.

3. Common Issues

Wear Signs: Excessive track sag, misalignment, or visible damage to idler wheels/seals.

Causes: Lack of lubrication, abrasive environments, or improper tension.

4. Replacement Tips

Tools Needed: Hydraulic jack, track press (for tension adjustment), torque wrench.

Steps:

Release track tension.

Remove track chain (if necessary).

Unbolt and replace idler assembly.

Re-tension track to CAT specs (refer to service manual).

5. Where to Buy

CQCtrack&DPW-parts

Cross-Reference: Provide your old idler’s specs to suppliers for matching.

6. Maintenance

Lubrication: Regularly grease idler bearings (use CAT-recommended grease).

Inspection: Check for leaks, cracks, or uneven wear during undercarriage checks.

Note

For accurate part numbers and procedures, always consult:

CAT E395 Service Manual (Section: Undercarriage).

Online Parts Catalogs (e.g., CAT Parts).

If you need help locating a specific part number or troubleshooting, share your machine’s serial number or a photo of the old idler.

![CATERPILLAR -E395[CR6380,7Y-0856]front idler ass'y/cat excavator carriage part/E350/E365/E374D/E375/E390/E395 idler factory](/uploadfile/202505/eefa23c5961a.webp)

![CATERPILLAR -E395[CR6380,7Y-0856]front idler ass'y/cat excavator carriage part/E350/E365/E374D/E375/E390/E395 idler factory](/uploadfile/202505/e1b55a56d496214.webp)

![CATERPILLAR -E395[CR6380,7Y-0856]front idler ass'y/cat excavator carriage part/E350/E365/E374D/E375/E390/E395 idler factory](/uploadfile/202505/97e56ad4f4d8bb6.webp)

![CATERPILLAR -E395[CR6380,7Y-0856]front idler ass'y/cat excavator carriage part/E350/E365/E374D/E375/E390/E395 idler factory](/uploadfile/202505/1a90da35b7b083.webp)